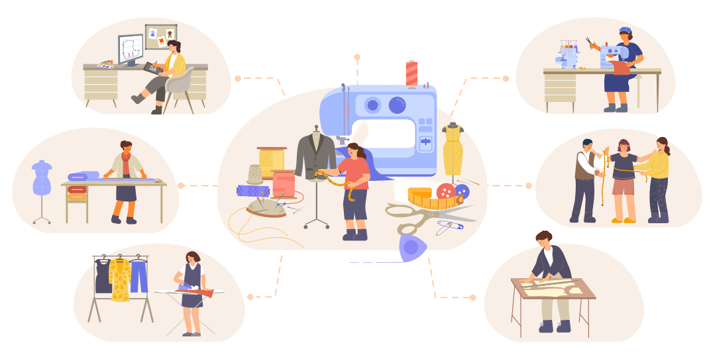

Our Process

We follows a consultive approach with the clients to better understand their purpose and sense of fashion to custom design uniforms for them. We are equiped with smart machineries and expert tailors to ensure proffessional quality in each uniform we manufacture. Uniforms are checked multiple times for deffects and damages before shipping them to the client

Client Meeting

We initiate our process with a consultive meeting with the clients so that we get a precise picture of their requirements. We will first try to educate them on the different factors to consider while designing a uniform such as the General profile of the wearer, the Image and identity of the institution, Comfort in wear, Purpose of work, Appearance & style, Climatic conditions of the place, Budget & value for money, Fabric, Ease of availability of material, etc so that it will be easier for them to define their requirement even more precisely. We will also make certain suggestions to make the design even more relatable to the wearer's individuality as well as the organization's reputation.

Client Meeting

Sample Construction

Once we acquire enough information, we will proceed to the sample construction process, of which the first step is designing. Sketches are made by keeping the brand identity, corporate colors, and wearer roles in the essence and by applying some design concepts and fashion elements. Two or more individual designs are made and handed over to the client for approval. Sample uniforms are also tailored on special requests. A few rounds of refinement in the Design and Sample construction bring out the perfect uniform. Once the client approves a design, color palettes, garments, fabric, styles, and logos are finalized.

Sample Construction

Garment Construction

Once the design is finalized, it is handed over to the mass production unit, where all the required fabric and materials are made available. Expert cutters cut the chosen fabric for different sections of each uniform for different sizes as per the design specifications. Experienced seamsters join the sections with perfect stitches to make the basic structure of the uniform. Buttons, hooks, and other necessary materials are attached to each item before stitching the logo of the organization. Each batch of uniforms is transferred for quality checking once the manufacturing process Is completed.

Garment Construction

Quality Assurance & Quality Control

It is not possible to produce perfectly stitched uniforms without stringent quality control. Each uniform is thoroughly examined by experts for defects such as Seam Puckering, Open or broken seam, Broken Stitch, Drop stitch/Skipped stitch, Uncut/ loose thread, Distorted knitting, Seam slippage, Needle threads breakage, etc. In order to make the corrections, all the defective pieces are transferred back to the production unit, where each piece will be modified as per the issues identified. Some items are manufactured again from the start if found irredeemable.

Quality Assurance & Quality Control

Product Delivery

Final checking is done before pressing and packing on the checking table so that any fault in the piece may be removed and protruding threads may be eliminated. Individual pieces are pressed by electric presses to remove any wrinkle marks. Uniforms are grouped as per the requirement sheet from the client and checked for quantity to ensure that the correct number of items are being packed. Once the final checking is done, uniforms are packed into the carton boxes and stacked into the delivery truck. The logistics team will ensure the proper delivery.

Product Delivery